In the architecture industry, there’s one person who dares to challenge the traditional concepts of architecture.

This innovator created new world-class projects based off of smooth line designs.

In 2004 she earned the Pritzker Architecture Prize and is known as the “Queen of the curves” among world-class architects, Zaha Hadid.

Beijing International Airport T4 Model which is designed by Zaha Hadid

Zaha Hadid Architects, founded by Zaha Hadid, has always had a strict attention to detail. As a result, it has never brought in a third party into the production process.

However, in a great honor, RJ Models collaborated with Zaha Hadid Architects in 2011 in Beijing airport design competition.

Zaha Hadid hired us three weeks before the competition to create an airport model. Our task was to ensure the safe delivery of the model to the competition site.

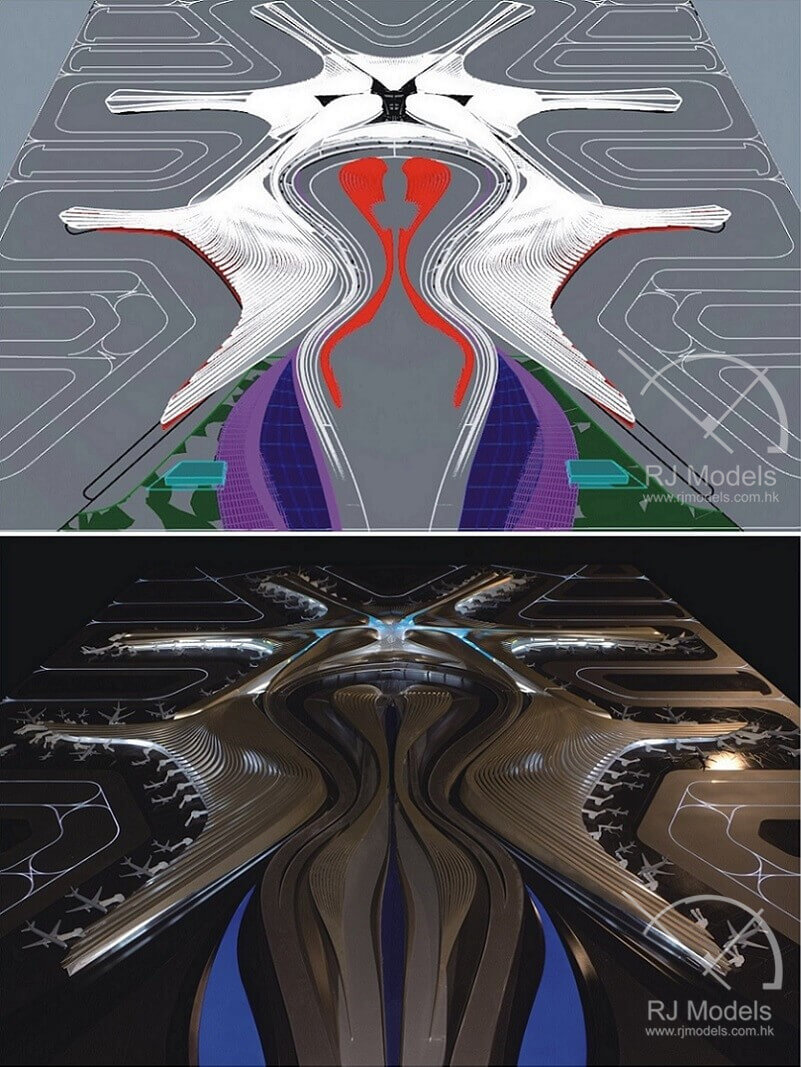

Zaha Hadid asked RJ Models to combine two models into a single one. The first model measures 3500 mm x 1500 mm and the second model measures 2500 mm x 2500 mm.

At the end of the competition when Zaha Hadid won, RJ Models also received recognition. This begins a new line of cooperation between two architectural giants.

The rest of this article details the process of cooperation between the two architectural giants. They worked together to overcome challenges in their first project to create a beautiful masterpiece.

1. The initial drawing stage:

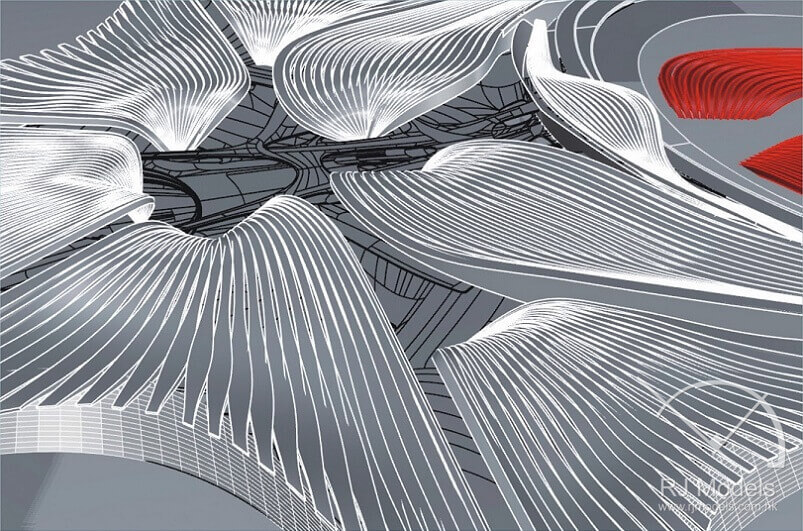

Zaha Hadid commissioned a concept model that had a ratio of 1:2000, with dimensions of 3500 mm x 1500 mm.

This architectural model was intended to provide an overhead view of the airport and the general idea appearance of the airport.

The next model would have a ratio of 1:1600 and a dimension of 2500 mm x 2500 mm and would be used to demonstrate the various zones of the airport and their functions.

Due to the time constraints, once RJ Models received the final design from Zaha Hadid using Rhino Software, they immediately marshaled a team of ten senior architectural model makers to check over the drawings and repurposed them to divide the airport into its different components.

This reorganization process would ensure a smooth production process and ensure project completion within the mandated timeline.

Beijing’s Daxing International Airport Model with Zaha Hadid’s process and challenges.

2. Panel (component manufacturing):

During the redrawing process, our architectural model makers in China had to devise a way to shrink the model on a scale of 600 to 1200 times smaller, while still maintaining the integrity of the curve found in the outer walls.

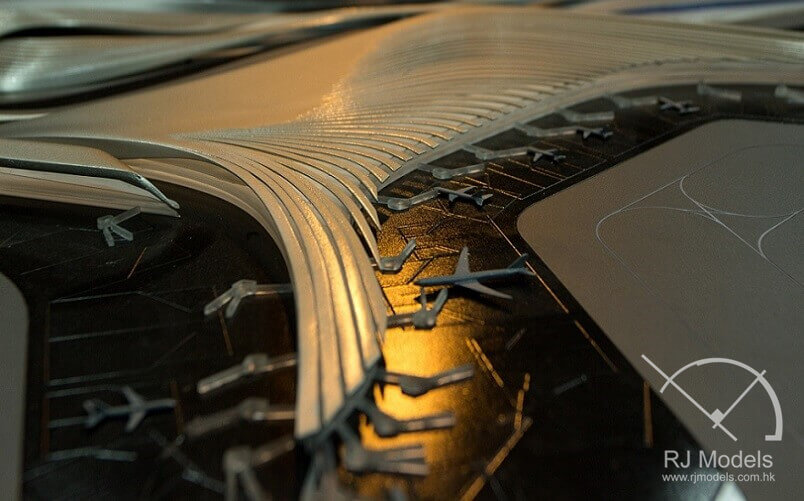

RJ Models utilized multiple CNC machines to quickly carve and produce the various pieces for assembly. This ensures precisely maintaining the flow within the curve of the walls.

Before putting the pieces together, the senior officers within the modeling division polished each individual piece. This is to achieve a shine necessary to show off the flair within the design.

For more specialized pieces such as the domed skylight, we used 3D printed architectural model technology to have those pieces ready for final assembly.

We gathered up the pieces and had 30 different workers working overtime to combine the pieces together and reinforce joints. In this way, the model could be safely delivered within the requested timeline.

3. Model painting:

The most important part of the model was how the exterior of the airport looked. Zaha Hadid’s design had an “ultramodern” feel to it.

We sprayed the exterior of the sample to exhibit the metallic feel of Zaha Hadid’s design.

4. The lighting of the model:

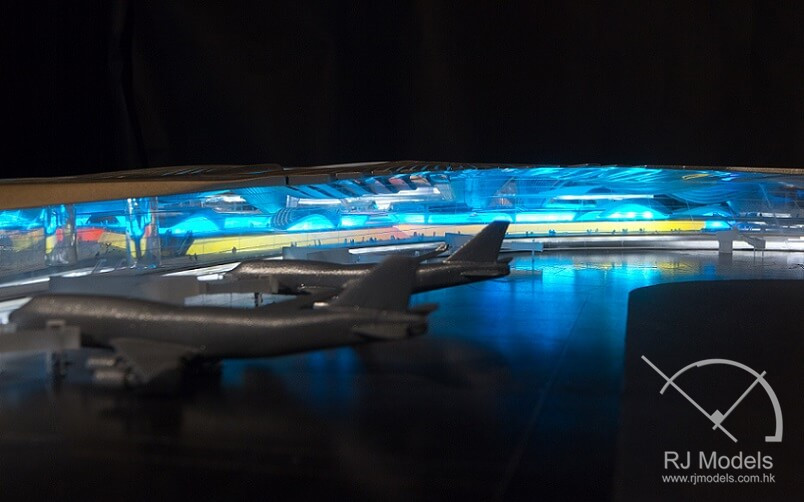

Adding lights to the model not only made the overall model stand out, but also impressed the competition judges.

For this, RJ Models used five different shades of lighting on the model, to demonstrate the airport’s areas and functions.

For example, arrival and departure had their own different colors.

Furthermore, the lighting controller was placed within easy reach of a presenter to help with the presentation of the model.

This helped effectively communicate to the judges the various features of the airports, and the themes behind each one.

5. Packaging and delivering:

To ensure a safe and rapid travel from Shenzhen to Beijing, our experienced packaging division meticulously produced a specialized box. Additionally, we assigned three different truck drivers to work in shifts, ensuring the model’s delivery within a tight 24-hour timeframe.

Therefore, they would meet five members of the construction division to finalize installation of the airport model.

Upon witnessing the remarkable speed and exceptional quality of the model’s production, Zaha’s review team expressed their utmost satisfaction.

Looking back, this project presented both challenges and immense personal gratification.

The winning design by Zaha has been officially selected as the new airport terminal T1 in Beijing’s Da Xing District.

Beijing Capital Airport

According to Zaha’s corporate partner ADPI, this airport will help relieve the stress on the current Beijing Capital Airport. It will become the world’s largest airport terminal, a key hub in Beijing’s economic and regional transportation network.

RJ Models was pleased to have participated in the outstanding design team and are proud of the work of airport models we have done.

Contact RJ Models & We can Help You to Grow Your Business.

Our vision is providing the top quality 3D scale models to everywhere in the globe.